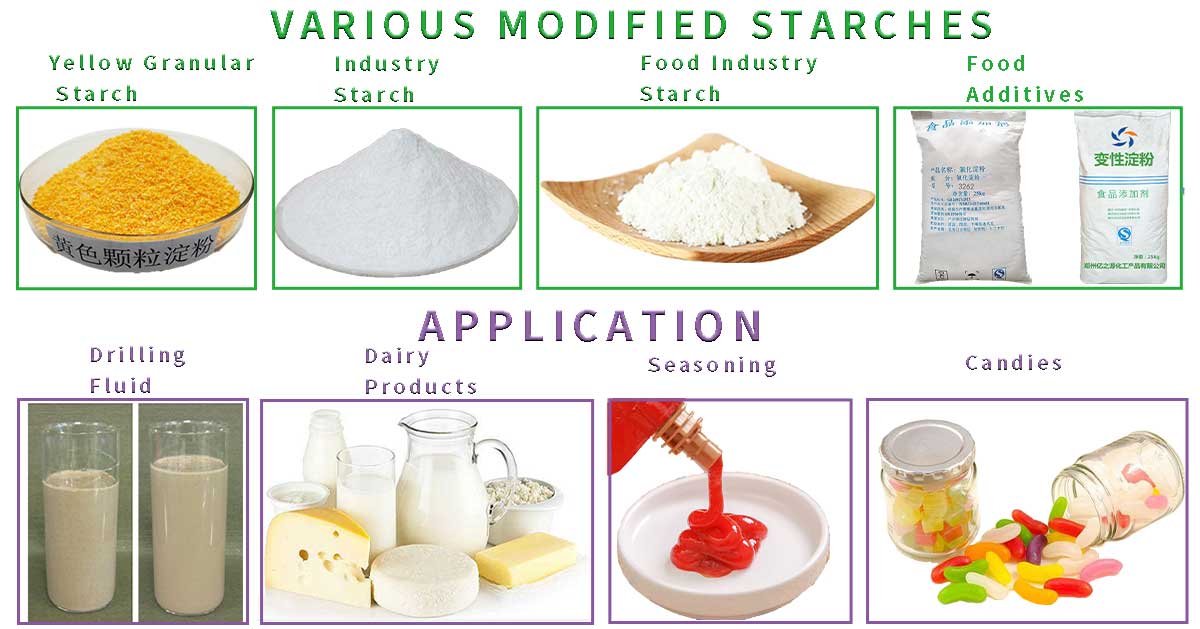

Final Products: Modified starch, pregelatinized starch, nutrition powder, baby rice flour, etc.

Capacity: 100kg/h-700kg/h

Raw Material: Corn flour, tapioca flour, potato flour, etc.

Certification: CE, ISO9001, SGS

| Model | TSE65 | TSE70 | TSE85 | TSE95 |

| Installed Power | 55KW | 70KW | 130KW | 150KW |

| Capacity | 100-150kg/h |

150-200kg/h |

300-400kg/h |

500-700kg/h |

| Dimension | 14×1.3×2.2m |

16×1.3×2.2m |

20×1.5×2.6m |

25×1.6×2.6m |

Introduction of Modified Starch:

In order to improve the performance of starch and expand its application range, physical, chemical or enzymatic treatment is used to introduce new functional groups on starch molecules or change the size of starch molecules and the properties of starch granules, thereby changing the natural characteristics of starch (such as: gelatinization temperature , thermal viscosity and its stability, freeze-thaw stability, gel strength, film-forming properties, transparency, etc.), making it more suitable for certain application requirements. This kind of starch that has undergone secondary processing and changed its properties is collectively called modified starch (also called denatured starch).

The purpose of denaturation is to adapt to the requirements of various industrial applications. For example: high-temperature technology (canning sterilization) requires starch to have good high-temperature viscosity stability, frozen food requires starch to have good freeze-thaw stability, and jelly food requires good transparency and film-forming properties. The second is to open up new uses of starch and expand the scope of application. Such as: starch used in textiles; hydroxypropyl starch instead of plasma; highly cross-linked starch instead of talcum powder for surgical gloves, etc.

Introduction of Our Modified Starch Production Equipment:

Our modified starch production line uses corn starch, tapioca starch, potato starch, etc. as the main raw materials, and adopts an extrusion process with a twin-screw extruder as the core equipment. The high temperature and high pressure of the raw materials in the extruder and the shear force of twin-screw mixing make the starch gelatinize and change the original physical and chemical properties of the starch, so as to produce modified starch with more excellent properties, making it suitable for production and life needs, has a wider use value. The modified starch produced by extrusion method is widely used in many industries such as food processing, feed, biopharmaceutical, cosmetics, foundry, building materials, textile, paper making, etc., and has a broad market prospect.

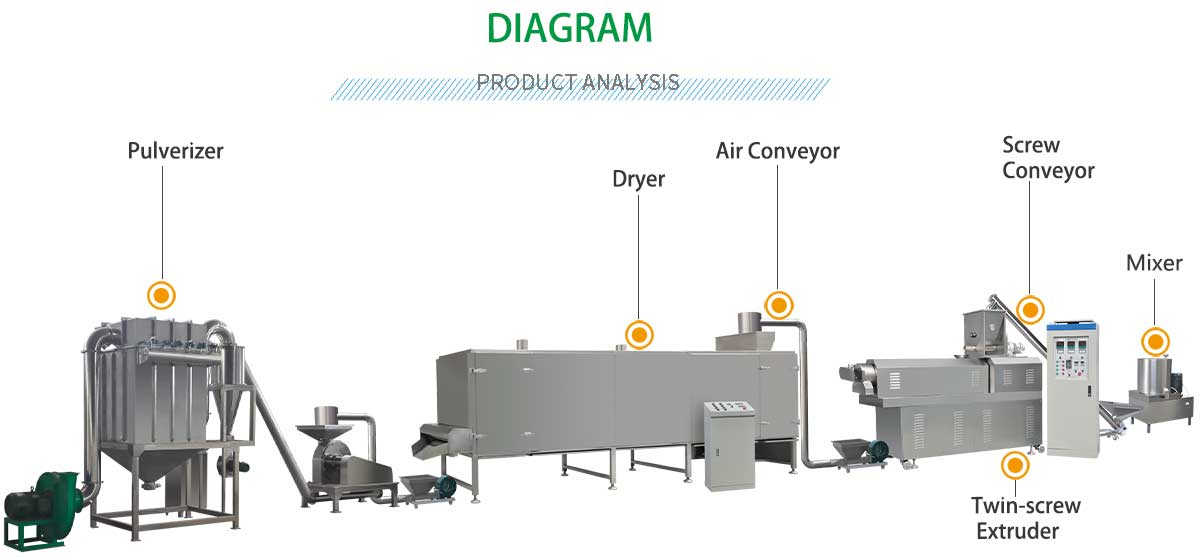

Modified Starch Production Line Configuration:

Mixer---Screw Conveyor---Twin-screw Extruder---Air Conveyor--- Multi-layer Dryer---Milling System

Equipment Features:

●Visual automatic temperature control system to make temperature control more intuitive and parameters more accurate

●The core machines adopts frequency speed controlling with high automation and stable per-formation.

●The screws of the extruder are made of alloy steel and special craft, durable usage, high hardness, and the screw life is longer. Adopting the building block structure and combining arbitrarily according to the different demands.

●The forced lubrication system, can guarantee the equipment transmission life longer.

●Self-cleaning, when stopping, the extruder can be cleaned without disassembling.

●According to different screw design rates to meet different technology request.

●This equipment has a wide raw material range, multi-shape products, and flexible collocations. We can produce different products according to the different models and configurations.

Output:

According to different configurations of the production line, the output range is 100kg/h--700kg/h

Video of Production Line Working:

Modified Starch Samples:

If you have any needs, please pay attention to them and we will reply to you as soon as possible

Chinese

Chinese English

English Russian

Russian