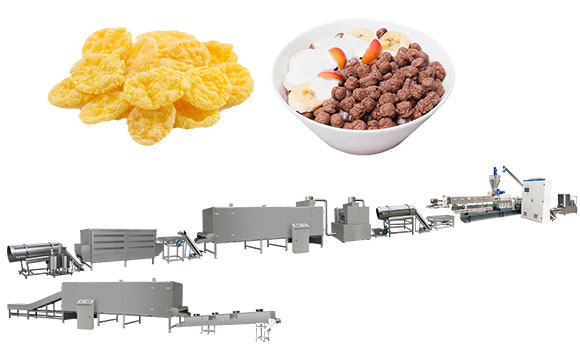

Final Products: Breakfast cereal flakes, corn flakes, cocoa puffs, froot loops,etc.

Capacity: 100kg/h-500kg/h

Raw Material: Corn flour, cereal flour, etc.

Certification: CE, ISO9001, SGS

| Model |

TSE65 |

TSE70 | TSE75 | TSE85 |

| Installed Power | 130KW | 160KW | 256KW | 275KW |

| Capacity | 100-120kg/h |

200-260kg/h |

250-350kg/h |

300-500kg/h |

| Dimension | 39×1.5×2.5m |

41×1.5×2.5m |

52×1.5×2.6m |

45×1.5×2.6m |

Production Line Introduction:

Corn flakes that are made by our machines usually take corn flour as the main raw material, adding sugar, various vitamins, and minerals. After adding a certain amount of water, they are fully kneaded, matured, shaped, pressed, baked, and seasoned. Through professional processing of professional equipment and technique, cornflakes will have cripy mouth-feeling and delicious taste. Corn flakes are nutritious and balanced, usually eaten with milk, it is a very popular cereal breakfast food. This production equipment can also make cocoa puffs cereal, froot loops cereal, and breakfast products in various shapes such as flakes, stars, and letters.

Production Line Flow Chart:

Raw Material Preparation→Flour Mixing→Extrusion→Tabletting→Low Temperature Drying→High Temperature Baking→Sugar Spraying and Seasoning→Drying→Cooling→Packaging

Configuration and Introduction of Cornflakes Production Line:

1. Flour Mixer: add corn flour, nutritional additives, and a certain proportion of water and mix evenly.

2. Screw Conveyor: transport the mixed raw materials to the feeding hopper of the extruder.

3. Extruder: The raw material in the feeding hopper enters the extrusion system to produce small spherical particles.

4. Vibrating Screen: to disperse the particles and avoid overlapping and pressing together after entering the tablet machine.

5. Air conveyor: transport the granules to the tablet machine.

6. Tabletmachine: Press small spherical particles into thin slices, which are cornflakes.

7. Air conveyor: transport the cornflakes into the oven.

8. Low-temperature oven: The oven is mostly an electric oven, the temperature is adjusted between 100-150 degrees by the control cabinet, and the inside is a stainless steel double-layer mesh belt (chain plate or Teflon mesh belt can also be selected), the baking time Can be adjusted according to speed to remove moisture.

9. High temperature oven: the temperature is between 150-220 degrees. The main function is to bake the cornflakes at high temperature to achieve a crispy effect.

10. Automatic seasoning line: sugar or seasoning for corn flakes and other products.

11. Climbing oven: drying sugar-sprayed corn flakes and other products (climbing oven is convenient for cleaning sugar and other seasonings left on the mesh belt).

12. Cooling conveyor: quickly cool the baked corn flakes and other products and transport them to the packaging machine.

Equipment Features:

●Visual automatic temperature control system to make temperature control more intuitive and parameters more accurate

●The main extruder adopts frequency speed controlling with high automation and stable per-formation.

●The screws are made of alloy steel and special craft, durable usage, high hardness, and the screw life is longer. Adopting the building block structure and combining arbitrarily according to the different demands.

●The forced lubrication system, can guarantee the equipment transmission life longer.

●Auto-temperature control system makes the temperature control more direct viewing and the parameter more precise.

●Self-cleaning, when stopping, can be cleaned without disassembling.

●According to different screw design rates to meet different technology request.

●This equipment has a wide raw material range, multi-shape products, and flexible collocations. The equipment can produce different products according to the different models and configurations.

Productive Capacity:

According to different configurations of the production line, the output range is 100kg/h--500kg/h

Equipment Working Video:

Breakfast Cereal Product Samples:

If you have any needs, please pay attention to them and we will reply to you as soon as possible

Chinese

Chinese English

English Russian

Russian