Final Products: Artificial rice(fortified nutrition rice, golden rice), artificial dal, couscous, etc.

Capacity: 100kg/h-900kg/h

Raw Material: Rice flour, corn flour, buckwheat flour, Konjak flour, etc.

Certification: CE, ISO9001, SGS

| Model | EXT100 | TSE70 | TSE75 | TSE95 |

| Installed Power | 90KW | 112KW | 160KW | 200KW |

| Capacity | 100-150kg/h | 120-180kg/h | 300-400kg/h | 500-900kg/h |

| Dimension |

21×1.3×2.2m |

22×1.5×2.2m |

25×1.5×2.6m |

35×1.6×2.6m |

Production Line Introduction:

The production line uses rice flour, corn flour, buckwheat flour, Konjak flour, etc. as the main raw materials, and can add vitamins, minerals and other nutritional elements to produce nutritionally fortified rice. The mixed powdery material is matured by a twin-screw extruder, extruded and granulated, then dried at low temperature and cooled to make artificial rice with various shapes and tastes. This processing technology not only retains the original ingredients of ordinary rice, but also supplements and strengthens the nutrients necessary for human health. The nutritional rice production line can not only produce nutritious rice such as miscellaneous grain rice, golden rice, konjak rice, green bamboo rice, but also artificial lentils, couscous rice and other foods.

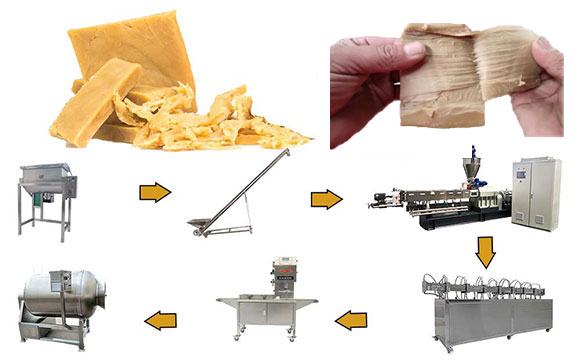

Production Line Flow Chart:

Raw Material Processing→Mixing(Mixer)→Extrusion, Maturing and Shaping(Rice Extruder)→Vibration and Cooling(Vibrating Screen)→Drying(Dryer)→Cooling(Cooling Conveyor)→Packaging(Packing Machine)

Equipment Features:

1. Feeding, rotary cutting, and main drive all adopt frequency conversion speed regulation system, which has strong power, stable operation and energy saving;

2. Proprietary screw combination technology, suitable for a wide range of raw materials, durable quality assurance;

3. Temperature control closed-loop control system, precise temperature control, stable product quality;

4. The barrel is equipped with a water injection port to better meet the requirements of raw materials and quality;

5. The shaking range of the vibrating screen is large, the incoming materials are evenly distributed without agglomeration, and the materials are evenly heated;

6. The penetrating dryer has high drying efficiency, and the moisture inside and outside the product is uniform; the product is crystal clear

7. Different electrical components can be equipped according to customer needs, such as Siemens motors, Delta/ABB/Siemens frequency conversion, ABB/Siemens touch screens, Chint/Siemens/ABB electrical components

Productive Capacity:

According to different configurations of the production line, the output range is 100kg/h--900kg/h

Video of the Production Line Working:

Artificial Rice Samples:

If you have any needs, please pay attention to them and we will reply to you as soon as possible

Chinese

Chinese English

English Russian

Russian