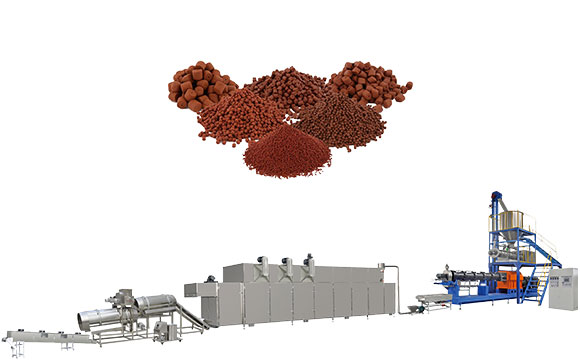

Final Products: Fish feed, shrimp feed, crab feed, bullfrog feed, soft-shelled turtle feed, dog food, cat food, etc.

Capacity: 100kg/h-1000kg/h

Raw Material: Grain or flour, soy meal, fish meal, etc.

Certification: CE, ISO9001, SGS

| Model | TSE65-P | TSE70 | TSE75 | TSE85 |

TSE90 |

| Installed Power | 74KW | 105KW | 120KW | 140KW |

160KW |

| Capacity | 100-150kg/h |

200-280kg/h |

300-400kg/h |

400-600kg/h |

800-1000kg/h |

| Dimension | 17×1.5×2.2m |

20×1.6×2.2m |

25×2.0×2.6m |

30×2.0×2.6m |

40×2.0×2.6m |

Production Line Introduction:

The small fish feed production line consists of a mixer, screw conveyor, twin-screw fish feed extruder, air conveyor, oven, seasoning machine, cooling conveyor, and packaging machine. Mainly used in the production of various floating, slow-sinking and sinking aquatic feeds (all kinds of adult fish feed, fry feeds, ornamental fish feeds, soft-shelled turtle feeds, shrimp feeds, bullfrog feeds, and fishing baits, etc.) and pet food such as dog food, cat food, etc. The technological process is continuous and reasonable, the performance of each stand-alone machine is good, and the operation and maintenance are convenient. The production equipment can adjust the process parameters such as raw materials, temperature, moisture, etc., and let the product has the characteristics of novel shape, unique taste, rich nutrition and fine texture.

Production Line Flow Chart:

Mixer→Screw Feeder→Fish Feed Extruder→Air Conveyor→Oven→Flavring Machine→Cooling Conveyor→Packing Machine

Configuration and Introduction of Small Fish Feed Production Line:

1. Mixer: fully mix the raw materials evenly according to a certain proportion.

2. Screw Conveyor: The motor is used as the driving force for screw conveying, and the mixed raw materials are conveyed to the feeding hopper of the extruder to ensure convenient and fast feeding.

3. Twin-screw Fish Feed Extruder: The high pressure and high temperature generated by the screw and barrel extrusion and the heating ring change the properties of the material and mature and expand the material, while killing harmful bacteria. Then the material is molded into a specific shape (such as fish feed) through a mold.

4. Air Conveyor: Transport materials from low to high.

5. Oven: Dry the feed, reduce the moisture of the feed granules, promote the ripening rate, and increase the shelf life.

6. Seasoning Machine: spray oil, spray medicine and other treatments on the feed.

7. Cooling Conveyor: Cooling and transferring the product.

The difference between twin-screw and single-screw fish feed extruder:

Twin-screw extruder is evolved from single-screw extruder. The main structural difference is that the screw has changed from one to two, and the heating ring has been added at the same time. , so that the processing temperature range is wider and the temperature can be controlled more accurately, so as to process higher quality and more stable products. The twin-screw extruder has larger output, more stable operation, simple operation and automatic cleaning function (automatic cleaning of waste can be completed without disassembling the screw). The more advanced twin-screw extruder also has a touch screen visual control system, which makes the control more precise and convenient.

Equipment Features:

●Visual automatic temperature control system to make temperature control more intuitive and parameters more accurate

●The main extruder adopts frequency speed controlling with high automation and stable per-formation.

●The screws are made of alloy steel and special craft, durable usage, high hardness, and the screw life is longer. Adopting the building block structure and combining arbitrarily according to the different demands.

●The forced lubrication system, can guarantee the equipment transmission life longer.

●Auto-temperature control system makes the temperature control more direct viewing and the parameter more precise.

●Self-cleaning, when stopping, can be cleaned without disassembling.

●According to different screw design rates to meet different technology request.

●This equipment has a wide raw material range, multi-shape products, and flexible collocations. We can produce different products according to the different models and configurations.

Productive Capacity:

According to different configurations of the production line, the output range is 100kg/h--1000kg/h

Equipment Working Video:

Feed Samples:

If you have any needs, please pay attention to them and we will reply to you as soon as possible

Chinese

Chinese English

English Russian

Russian