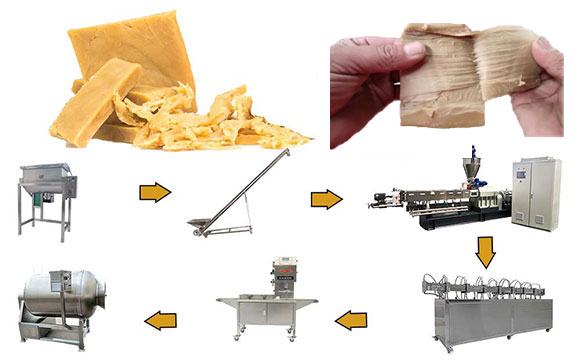

Final Products: Vegetable protein in lumps, flakes, columns and granules, textured soybean protein, etc.

Capacity: 200kg/h-1000kg/h

Raw Material: Low-temperature defatted soy meal, etc.

Certification: CE, ISO9001, SGS

| Model | TSE65-S | TSE75-S | TSE85-S |

TSE95-S |

| Installed Power | 90KW |

130KW |

160KW |

210KW |

| Capacity | 200-260kg/h |

250-360kg/h |

300-500kg/h |

800-1000kg/h |

| Dimension | 18×1.3×2.3m |

20×1.6×2.6m |

22×1.6×2.6m |

35×1.6×2.6m |

Production Line Introduction:

Textured soya protein production line is a kind of production equipment for producing high protein and high fiber plant protein introduced by our company to the market according to the needs of domestic and foreign markets and years of extrusion technology. The core equipment of this production line is a soya protein extruder. Under the action of high temperature, high pressure and high shear force in the extruder, the protein is textured. The products produced have strong meat texture, good fiber state and high toughness, and are favored by manufacturers. The product can be added to ham, sausage, canned food and various ready-to-eat foods to increase the chewiness of food.

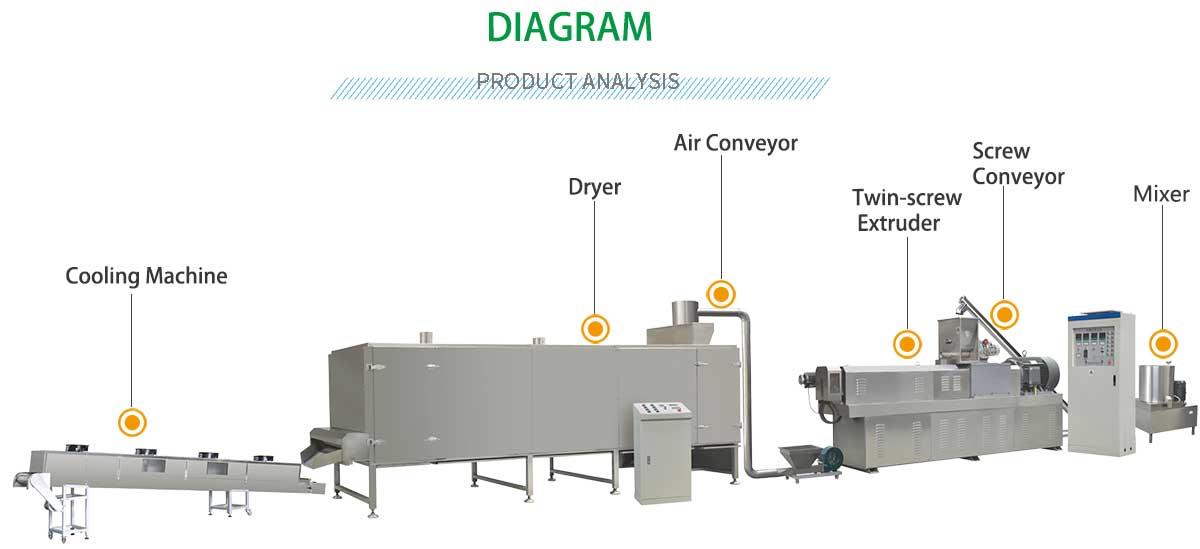

Production Line Flow Chart:

Mixer→Screw Conveyor→Soya Protein Extruder→Hoister→Dryer→Cooling Machine

Configuration and Introduction of Textured Soya Protein Production Line:

1. Mixer: Fully mix the raw materials evenly according to a certain proportion.

2. Screw Conveyor: The motor is used as the driving force for screw conveying, and the mixed raw materials are conveyed to the feeding hopper of the extruder to ensure convenient and fast feeding.

3. TVP Extruder: Extruding and puffing the raw material and rearranging its protein molecules into meat-like fibrous tissue.

4. Elevator: Transport the undried plant protein from the extruder to the oven.

5. Oven: Dry the protein products.

6. Cooling Machine: Cooling the protein products and dry them further more.

Features of the Production Line:

●Mainly use defatted soybean flour as raw materials, with large market supply and low cost.

●Under the action of short-term high temperature and high pressure, various harmful substances contained in soybeans (trypsin inhibitor, urease, saponin and hemagglutinin, etc.) are eliminated, and the human body's ability to absorb and digest protein is improved. Significantly increased nutritional value;

●When puffing in the extruder, due to the rapid decompression and explosion at the outlet, it can remove the bad smell in soybeans and reduce the gas production of soybean protein after eating;

●Visual automatic temperature control system to make temperature control more intuitive and parameters more accurate

●The core machines adopts frequency speed controlling with high automation and stable per-formation.

●The screws of extruder are made of alloy steel and special craft, durable usage, high hardness, and the screw life is longer. Adopting the building block structure and combining arbitrarily according to the different demands.

●The forced lubrication system, can guarantee the equipment transmission life longer.

●Self-cleaning, when the extruder stop work, it can be cleaned without disassembling.

Output:

According to different configurations of the production line, the output range is 200kg/h--1000kg/h

Video of Production Line Working:

Samples of Plant Protein:

If you have any needs, please pay attention to them and we will reply to you as soon as possible

Chinese

Chinese English

English Russian

Russian