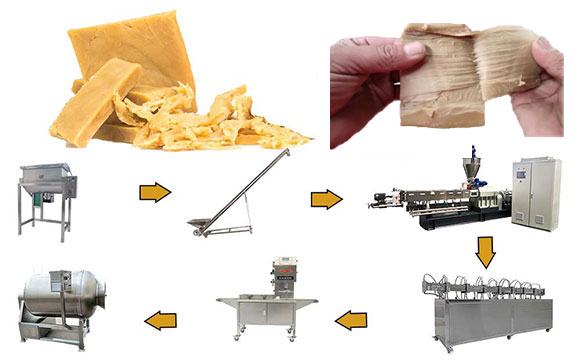

Final Products: Fibrosis vegetable protein, textured soya protein, etc.

Capacity: 200kg/h-350kg/h

Raw Material: Low-temperature soybean meal, soybean protein isolate, etc.

Certification: CE, ISO9001, SGS

| Model | TSE65-S | TSE75-S |

| Installed Power | 90KW | 140KW |

| Capacity | 200-260kg/h | 250-350kg/h |

| Dimension | 18×1.3×2.2m |

20×1.6×2.6m |

Production Line Introduction:

Fibrosis protein is a fibrous vegetable protein with muscle fiber texture produced by using low-temperature soybean meal, soybean protein isolate, gluten, etc. as the main raw materials, and using twin-screw extrusion technology. The raw materials are produced in an extruder specializing in the production of vegetable protein through crushing and kneading, shear,melting, protein recombination, high-temperature sterilization, extrusion,molding and other processes. Fibrosis protein in different shapes such as cylinders, blocks, sheets, strips, and granules can be produced according to different needs.

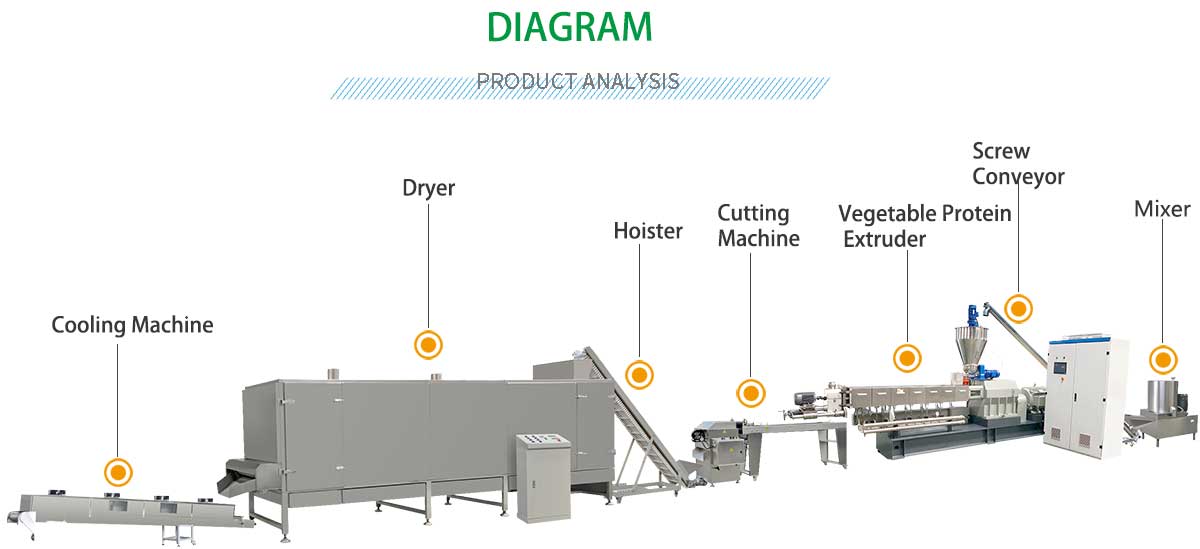

Production Line Flow Chart:

Powder Mixer → Fibrosis Protein Extruder → Air Conveyor → Oven → Cooling Conveyor

Fibrosis Vegetable Protein Production Line configuration and main machine introduction:

1. Powder mixer: fully mix the raw materials evenly according to a certain proportion (large-scale production lines can be equipped with automatic raw material processing systems, intelligent operating systems, more accurate ingredients, and higher work efficiency).

2. Screw conveyor: The motor is used as the driving force for screw conveying, and the mixed raw materials are conveyed to the feeding hopper of the extruder to ensure convenient and quick feeding.

3. Fibrosis Vegetable Protein extruder: shear and melt raw materials, and reorganize protein molecules into vegetable protein tissue with muscle fiber texture.

4. Air Conveyor: Conveys the undried vegetable protein from the extruder to the oven.

5. Oven: Dry protein products.

6. Cooling machine: to cool the protein products and further dry them.

Equipment Features:

●Visual automatic temperature control system to make temperature control more intuitive and parameters more accurate

●The core machines adopts frequency speed controlling with high automation and stable per-formation.

●The screws of the extruder are made of alloy steel and special craft, durable usage, high hardness, and the screw life is longer. Adopting the building block structure and combining arbitrarily according to the different demands.

●The forced lubrication system, can guarantee the equipment transmission life longer.

●Self-cleaning, when stopping, the extruder can be cleaned without disassembling.

●According to different screw design rates to meet different technology request.

●This equipment has a wide raw material range, multi-shape products, and flexible collocations. We can produce different products according to the different models and configurations.

Output:

According to different configurations of the production line, the output range is 100kg/h--700kg/h

Video of Production Line Working:

Fibrosis Vegetable Protein Samples:

Application of fibrosis vegetable protein:

The general state of fibrosis vegetable protein is dry solid (moisture content is about 10%, water activity Aw is about 0.43), and fibrosis vegetable protein must be softened by absorbing water before use. After fully absorbing water, the fibrosis vegetable protein will be completely softened and show the texture of fleshy fiber silk.

1. It is very suitable for processing all kinds of high-grade vegetarian imitation meat foods, such as vegetarian ham, vegetarian chicken, vegetarian fish, vegetarian burger, vegetarian hot dog, vegetarian steak, vegetarian meat floss, etc.

2. Additives for high-protein meat products. In the application of meat products, it can achieve the purpose of enhancing the meat texture, reducing the cost and increasing the protein content in the product. For example, it is used in quick-frozen meat products such as minced meat sausages, Western-style ham, meatballs, reorganized steaks (chicken chops, pork chops, etc.), fried chicken nuggets, hamburger, meat dumplings, buns, etc.; Snack foods such as beef jerky, and restructured beef cubes are also excellent choices.

3. It can be adjusted to make dishes or used as a substitute for some meat products, so it can be directly purchased by canteens, catering companies, restaurants, etc. This product is not only easy to operate, but also advocates a new concept of healthy and nutritious diet. At the same time, it can achieve the effect of reducing costs (less than 1/2 of the cost of lean meat), and is a new trendy food choice.

If you have any needs, please pay attention to them and we will reply to you as soon as possible

Chinese

Chinese English

English Russian

Russian