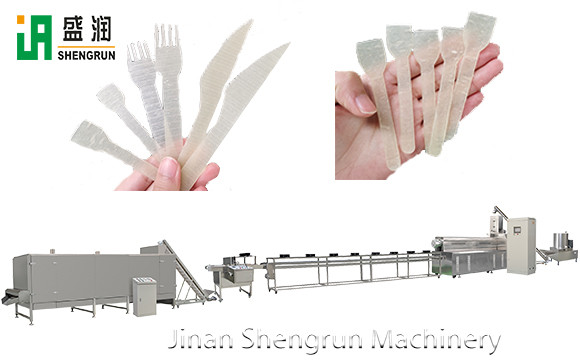

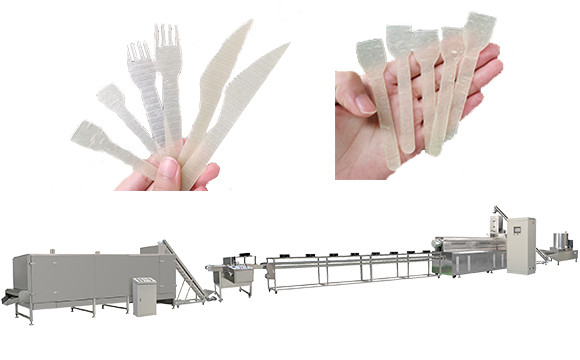

Final Products: Edible rice drinking straw, edible cutlery such as knife/fork/spoon, pasta, snacks, etc.

Capacity: 100kg/h-300kg/h(about 10000-30000pieces/h).

Raw Material: Rice flour, tapioca starch, etc.

Certification: CE, ISO9001, SGS

| Model | EXT100 | EXT130 |

| Installed Power | 100KW | 200KW |

| Capacity | 100-150kg/h |

200-300kg/h |

| Dimension | 50×2.0×2.2m |

60×2.0×2.6m |

Edible Cutlery and Prodction Line Introduction:

The research and development of edible tableware such as edible straws/knives/forks/spoons aim to solve the white pollution caused by plastic tableware. Nowadays, with the continuous emergence of environmental pollution problems, most countries in the world have begun to realize the importance of protecting the environment, and many countries have formulated laws and regulations on environmental protection. Plastic waste pollution is a kind of pollution that is extremely harmful to nature. Due to low cost and convenient use, plastic products are widely used in people's daily life. However, because it is difficult to degrade, it has brought great harm to the natural environment. Degradable tableware such as knives/forks/straws are made from natural raw materials such as corn flour/cassava flour. Not only can they degrade quickly after being discarded, but they can also be made into food-grade standards and eaten directly without causing any harm to the environment. So it is a very good substitute for plastic products.

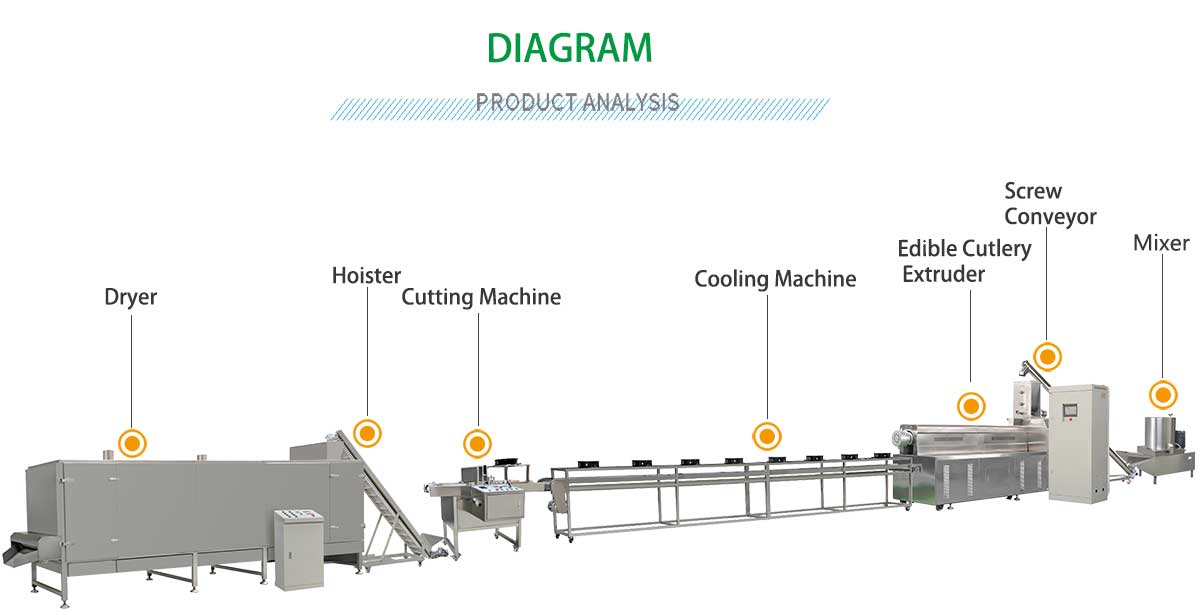

Production Line Configuration and Description:

①Mixer→②Screw Conveyor→③Edible Dinnerware Extruder→④Multifunctional Shaping Machine→⑤Elevator→⑥Multi-layer Dryer→⑦Cooling Conveyor→⑧Packing Machine

①The mixer is used for treating raw materials.

②The screw-conveyor is used for delivering treated raw material from mixer to extruder.

③The extruder is used for curing, extruding raw material and forming the raw material into prime shape.

④The multi-function shaper is used for forming specific tableware shape.

⑤The hoister is used for delivering products from multi-function shaper to multi-layer dryer.

⑥The dryer is used for drying tableware. According to the different energy sources, we have electric dryers, steam dryers, oil/gas dryers for you to choose from.

⑦The cooling machine is used for cooling and drying tableware.

⑧The packing machine is used for packing tableware.

Equipment Features:

●Visual automatic temperature control system to make temperature control more intuitive and parameters more accurate

●The core machines adopts frequency speed controlling with high automation and stable per-formation.

●The screws of the extruder are made of alloy steel and special craft, durable usage, high hardness, and the screw life is longer. Adopting the building block structure and combining arbitrarily according to the different demands.

●The forced lubrication system, can guarantee the equipment transmission life longer.

●Self-cleaning, when stopping, the extruder can be cleaned without disassembling.

●According to different screw design rates to meet different technology request.

●This equipment has a wide raw material range, multi-shape products, and flexible collocations. We can produce different products according to the different models and configurations.

Output:

According to different configurations of the production line, the output range is 100kg/h--300kg/h(about 10000-30000pieces/h).

Video of Production Line Working:

Edible Cutlery Samples:

If you have any needs, please pay attention to them and we will reply to you as soon as possible

Chinese

Chinese English

English Russian

Russian