Final Products: Eco friendly packing peanuts, biodegradable packing filler, foam packing pellets, packing material, etc.

Capacity: 100kg/h-400kg/h.

Raw Material: Corn starch, tapioca starch, etc.

Certification: CE, ISO9001, SGS

|

Model |

TSE70 |

TSE85 |

| Installed Power | 70KW |

130KW |

| Capacity | 150-200kg/h |

300-400kg/h |

| Dimension | 16×1.3×2.2m |

20×1.5×2.6m |

Biodegradable Packing Filler Foam Peanuts and Prodction Line Introduction:

Packaging foam peanuts are widely used in many industries, and its function is to protect the goods from damage during transportation. Usually packing peanuts are made of plastic, so they can damage the environment. Now the new biodegradable packaging foam peanuts are made of cheap natural starch, corn starch or tapioca starch as raw materials, and are made by extrusion technology, which is not harmful to the environment.

Biodegradable filling packing material production line is kind of new application of extrusion technology.

The line uses cheap natural starch, maize/corn starch, and tapioca starch as main materials, through the extruding treatment process by a twin screw extruder to be processed into a kind of starch-based foam material without any additive vesicant which can be fully biodegradable.

Biodegradable filling packing material can be widely used, such as packaging and filling material which can fill in the items packaging space quickly and evenly. It can be used on electrical products, precision instruments etc. since its functions of buffer and shock-absorption. What's more, it can be used as "educational sticky toys” and “DIY corn kernels” etc. After lightly wet, it can be bonded with the other materials, and create infinite styles.

Biodegradable filling packing material is applied widely since it is green, safe for children and environment biodegradable, nontoxic, lightweight, Anti-static etc.

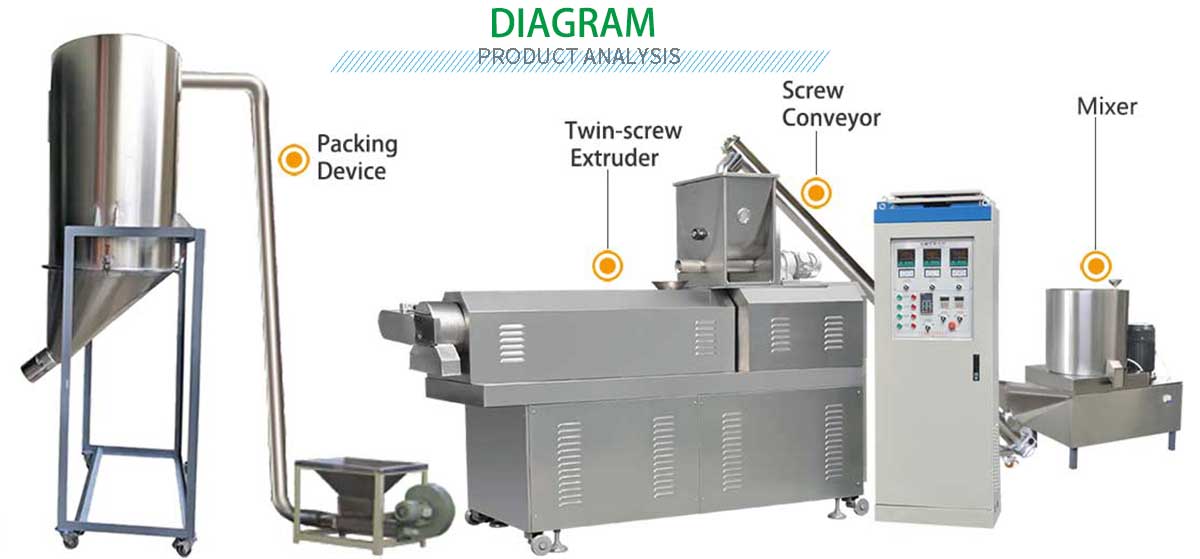

Production Line Configuration:

Mixer→Screw-conveyor→Twin-screw Extruder→Packing Device

①The mixer is used for treating raw materials.

②The screw-conveyor is used for delivering treated raw material from mixer to extruder.

③The twin-screw extruder is used for curing, extruding raw material and forming the raw material into prime shape.

④The packing device is used for packing foam peanuts.

Equipment Features:

●Visual automatic temperature control system to make temperature control more intuitive and parameters more accurate

●The core machines adopts frequency speed controlling with high automation and stable per-formation.

●The screws of the extruder are made of alloy steel and special craft, durable usage, high hardness, and the screw life is longer. Adopting the building block structure and combining arbitrarily according to the different demands.

●The forced lubrication system, can guarantee the equipment transmission life longer.

●Self-cleaning, when stopping, the extruder can be cleaned without disassembling.

●According to different screw design rates to meet different technology request.

●This equipment has a wide raw material range, multi-shape products, and flexible collocations. We can produce different products according to the different models and configurations.

Output:

According to different configurations of the production line, the output range is 100kg/h--400kg/h.

Video of Production Line Working:

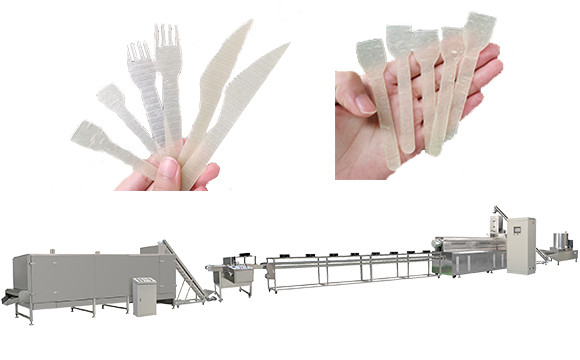

Biodegradable Packing Filler Foam Peanut Samples:

If you have any needs, please pay attention to them and we will reply to you as soon as possible

Chinese

Chinese English

English Russian

Russian