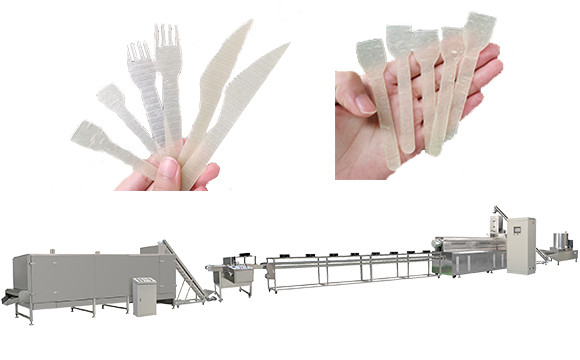

Final Products: Edible rice drinking straw, edible cutlery such as knife/fork/spoon, pasta, etc.

Capacity: 100kg/h-300kg/h(about 10000-30000pieces/h).

Raw Material: Rice flour, tapioca starch, etc.

Certification: CE, ISO9001, SGS

|

Model |

EXT100 |

EXT130 |

|

Installed Power |

100KW |

200KW |

|

Capacity |

100-150kg/h |

200-300kg/h |

|

Dimension |

50m*2.0m*2.2m |

60m*2.0m*2.6m |

Edible Rice Drinking Straw Introduction:

Edible rice drinking straws are an environmentally friendly and degradable straw that has become popular in recent years. Since the main raw material for making straws is rice flour, it is also called rice straws. In addition to being used as straws for drinking beverages, edible rice straws can also be eaten as food. The taste of directly eating is similar to snacks such as rice crackers; after cooking, it can be made into delicacies similar to pasta. High-quality straws will hold their shape for a long time when stored in good conditions; they will stay firm for hours in hot drinks and even longer in cold drinks.

With the implementation of the plastic ban, the demand for biodegradable straws has begun to increase. Since 2018, Shengrun Machinery has developed rice straws that are completely degradable in the natural environment. The formula and process have been improved many times to achieve the characteristics of translucent tube body, smooth and free of bubbles, high hardness, rich colors and resistance to immersion.

Compared with paper straws, which are astringent and not resistant to soaking, rice straws have a rice aroma and are more resistant to soaking.

Edible Rice Straw Production Equipment Introduction:

The rice straw production line uses rice flour, tapioca starch, etc. as the main raw materials. Straw blanks of different diameters are made by a straw extruder, cut into straws of different shapes and sizes by a cutting machine, and then dried in a special oven. The produced straws are smooth in appearance, translucent in texture, and thin on the wall (saving raw materials). On the way to achieving today's high-level craftsmanship, the company also encountered defects such as too thick of the wall, too many air bubbles, bending, and cracking in the straws produced by the equipment. After vigorous investment and repeated research, all difficulties were finally overcome. Therefore, it is recommended that when customers purchase equipment, they must go to the site to verify whether the straws produced by the equipment have the above defects. Avoid spending a lot of money to buy back equipment that can only produce defective products, or even fail to produce products, and become victims of sellers who steal pictures and videos of other people's products. Our company has three major brands: Jinan Shengrun, Jinan Senrun, and Jinan Sunward. In addition to many end users in China, there are also many users in Vietnam, South Korea, Malaysia, Germany, Canada, and other countries who are using our equipment for the production of edible rice straws. In addition to producing edible straws, this production line only needs to replace individual equipment to produce edible knives, forks, spoons, and other tableware, as well as food such as pasta.

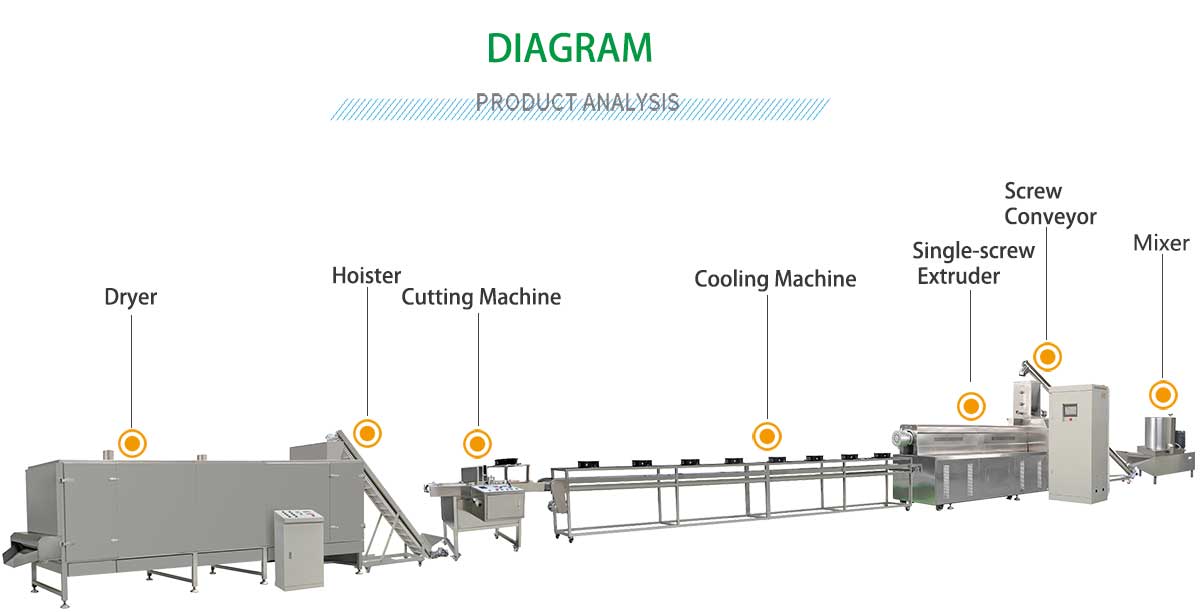

Production Line Configuration:

The production line has been verified by a large number of users, and the configuration is scientific and reasonable, simple and practical.

Mixer→Screw Conveyor→Edible Straw Extruder→Cutting Machine→Hoist→Edible Straw Dryer→Packing Machine

Equipment Features:

●Visual automatic temperature control system to make temperature control more intuitive and parameters more accurate

●The core machines adopts frequency speed controlling with high automation and stable per-formation.

●The screws of the extruder are made of alloy steel and special craft, durable usage, high hardness, and the screw life is longer. Adopting the building block structure and combining arbitrarily according to the different demands.

●The forced lubrication system, can guarantee the equipment transmission life longer.

●Self-cleaning, when stopping, the extruder can be cleaned without disassembling.

●According to different screw design rates to meet different technology request.

●This equipment has a wide raw material range, multi-shape products, and flexible collocations. We can produce different products according to the different models and configurations.

Output:

According to different configurations of the production line, the output range is 100kg/h--300kg/h(about 10000-30000pieces/h).

Video of Production Line Working:

Edible Rice Drinking Straw Samples:

Edible Rice Drinking Straws Application:

Project Cases:

If you have any needs, please pay attention to them and we will reply to you as soon as possible

Chinese

Chinese English

English Russian

Russian