Final Products: Various shapes of 3D three-dimensional, 2D puffed snacks..

Capacity: 100kg/h-800kg/h

Raw Material: Wheat flour, corn flour, rice flour, cassava flour, etc.

Certification: CE, ISO9001, SGS

|

Model |

TSE65 |

TSE70 |

TSE75 |

TSE78 |

|

Installed Power |

88KW |

126KW |

150kw |

170kw |

|

Capacity |

100-150kg/h |

200-260kg/h |

300-500kg/h |

500-800kg/h |

|

Dimension |

21m*1.6m*2.2m |

30m*1.6m*2.2m |

35m*2.0m*2.6m |

40m*2.2m*2.8m |

3 D Leisure Snacks Production Line Introduction:

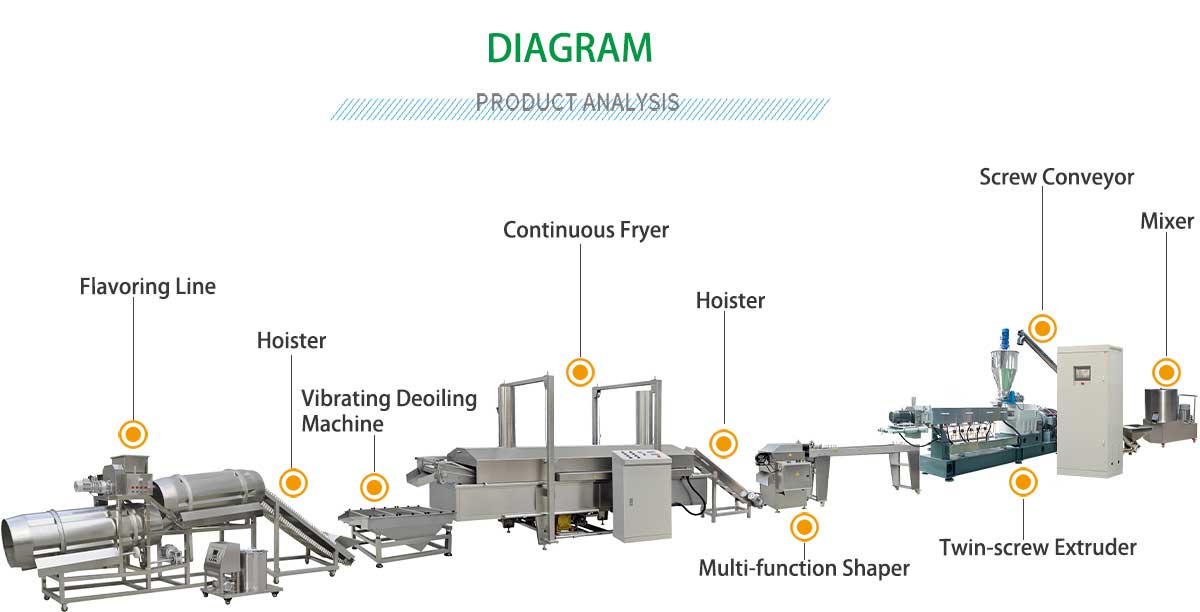

The production line can use wheat flour, corn flour, corn starch, tapioca starch, potato starch, etc. as raw materials, adopts food extrusion technology, and directly extrudes through twin-screw extruder or single-screw extruder (simple shape) or through rollers Pressing (complex shapes) can produce 2D and 3D snack blanks of various shapes such as network crisps, duck egg rounds, small fish crisps, golden horns, ducklings, gourds, peanuts, pagodas, letters and numbers, etc., and then drying,frying and seasoning, it can be made into 2D casual snacks or 3D three-dimensional casual snacks with realistic shapes and delicate and crisp taste. The production line has reasonable design, advanced production technology, high degree of automation, stable performance and flexible configuration, which can realize extrusion, curing, composite molding, frying, seasoning and packaging in one.

Production Line Flow Chart:

Raw Material Mixing→Extrusion→Shaping and Cutting→Frying→Deoiling→Seasoning→Packaging (equipment configuration is flexible)

Equipment Features:

●Visual automatic temperature control system to make temperature control more intuitive and parameters more accurate

●The main extruder adopts frequency speed controlling with high automation and stable per-formation.

●The screws are made of alloy steel and special craft, durable usage, high hardness, and the screw life is longer. Adopting the building block structure and combining arbitrarily according to the different demands.

●The forced lubrication system, can guarantee the equipment transmission life longer.

●Self-cleaning, when stopping, can be cleaned without disassembling.

●According to different screw design rates to meet different technology request.

●This equipment has a wide raw material range, multi-shape products, and flexible collocations. We can produce different products according to the different models and configurations.

Output:

According to different configurations of the production line, the output range is 100kg/h--800kg/h

Video of Production Line Working:

If you have any needs, please pay attention to them and we will reply to you as soon as possible

Chinese

Chinese English

English Russian

Russian