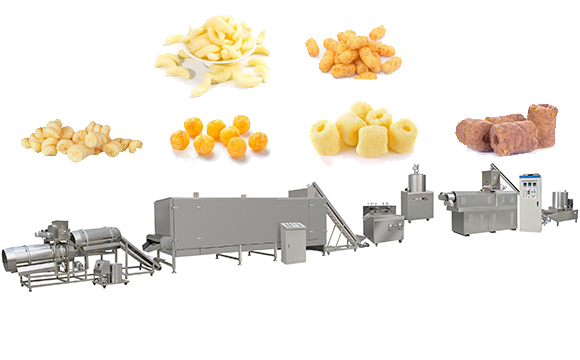

Final Products: Core filling snacks, corn sticks/fingers, cheese balls, etc.

Capacity: 100kg/h-1200kg/h

Raw Material: Grain flours,etc.

Certification: CE, ISO9001, SGS

| Model |

TSE65 |

TSE70 |

TSE75 |

TSE85 |

TSE95 |

|

Installed Power |

74KW |

105KW |

120KW |

140KW |

160KW |

|

Capacity |

100-150kg/h |

200-260kg/h |

300-400kg/h |

400-600kg/h |

800-1200kg/h |

|

Dimension |

17*1.5*2.2m |

20*1.6*2.3m |

25*1.8*2.6m |

30*1.8*2.6m |

40*2.0*3.5m |

Production Line Introduction:

The core filling snack production line is to inject cream, chocolate, peanut butter and other fillings with different flavors into the puffed food when the twin-screw food extruder extrudes the puffed hollow roll or small pillow-shaped snacks, thus giving the puffed food a richer taste.

The production line uses grain flour such as rice flour, corn flour as the main raw materials, adopts advanced co-extrusion technology, and uses a core filling machine to inject fillings and extrude them at the same time during the puffing process. The outside is puffed grains and the inside is fillings. In addition, different molds can be replaced to produce various shapes of puffed leisure snacks, and the screw and some auxiliary equipment can also be replaced to produce fried puffed snacks.

Production Line Flow Chart:

Raw Material Mixing→Extrusion and filling fillings→Shaping and Cutting→Baking→Seasoning→Packaging (equipment configuration is flexible)

Equipment Features:

●Visual automatic temperature control system to make temperature control more intuitive and parameters more accurate

●The main extruder adopts frequency speed controlling with high automation and stable per-formation.

●The screws are made of alloy steel and special craft, durable usage, high hardness, and the screw life is longer. Adopting the building block structure and combining arbitrarily according to the different demands.

●The forced lubrication system, can guarantee the equipment transmission life longer.

●Auto-temperature control system makes the temperature control more direct viewing and the parameter more precise.

●Self-cleaning, when stopping, can be cleaned without disassembling.

●According to different screw design rates to meet different technology request.

●This equipment has a wide raw material range, multi-shape products, and flexible collocations. We can produce different products according to the different models and configurations.

Productive Capacity:

According to different configurations of the production line, the output range is 100kg/h--400kg/h

Video of the Production Line:

Snacks Samples:

If you have any needs, please pay attention to them and we will reply to you as soon as possible

Chinese

Chinese English

English Russian

Russian