Final Products: Acicular breadcrumbs, granular breadcrumbs, flaky breadcrumbs, panko breadcrumbs, etc.

Capacity: 100kg/h-800kg/h

Raw Material: Flour, etc.

Certification: CE, ISO9001, SGS

|

Model |

TSE65 |

TSE70 |

TSE85 |

TSE95 |

| Installed Power | 71KW |

94KW |

120KW | 160KW |

| Capacity | 100-120kg/h |

180-240kg/h |

300-400kg/h | 600-800kg/h |

| Dimension | 19×1.6×2.2m | 21×1.3×2.2m | 25×1.5×2.6m | 30×1.6×2.6m |

Production Line Introduction:

Bread crumbs are a widely used food additive, used on the surface of fried food, such as fried chicken, fish, seafood (shrimp), chicken legs, chicken wings, onion rings, etc., its primary function is to delay the food from being fried burnt, and can achieve the effect of crispy on the outside and tender on the inside.

Traditional bread crumbs are made from toasted bread after being peeled, sliced, dried at a constant temperature, and then crushed. The process is cumbersome, low in efficiency, and high in cost. The bread crumb production line developed by our company has changed the traditional bread crumb production process, from the fermentation production process to the direct extrusion process, which simplifies the production process, and the remaining materials can be reused without waste, which improves the product quality and reduces the production cost and increased labor productivity.

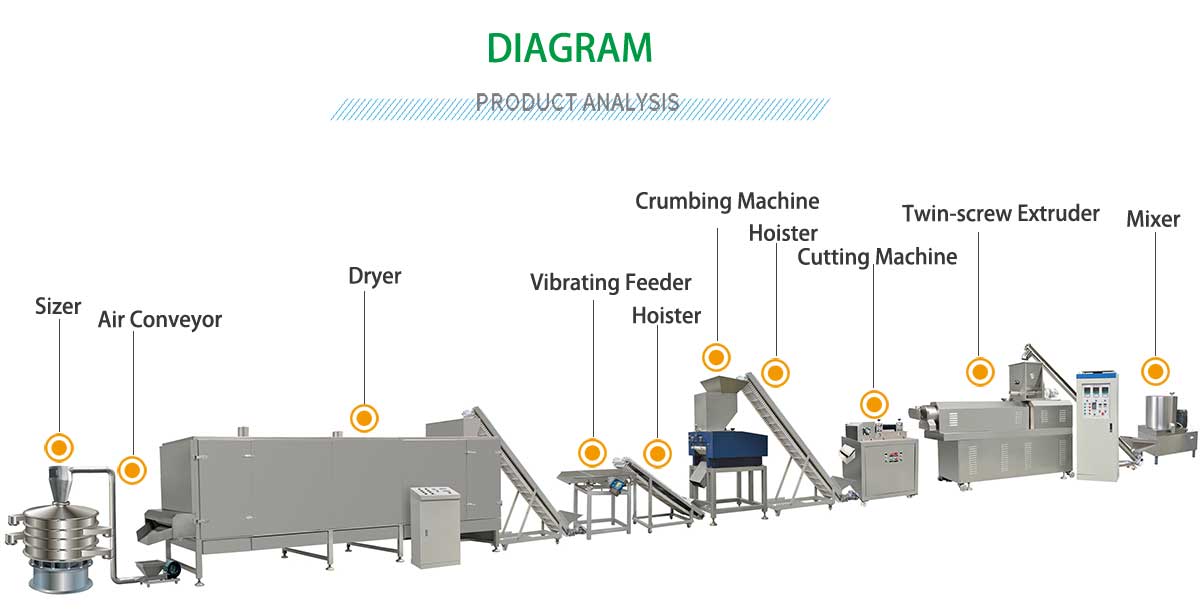

Production Line Flow Chart:

Mixer→Screw-conveyor→Breadcrumb Extruder→Cutting Machine→Hoister→Crumbing Machine→Hoister→Vibrating Screen→Hoister→Dryer→Air Conveyor→Sizer Packaging Machine(equipment configuration is flexible)

Equipment Features:

●Visual automatic temperature control system to make temperature control more intuitive and parameters more accurate

●The main extruder adopts frequency speed controlling with high automation and stable per-formation.

●The screws are made of alloy steel and special craft, durable usage, high hardness, and the screw life is longer. Adopting the building block structure and combining arbitrarily according to the different demands.

●The forced lubrication system, can guarantee the equipment transmission life longer.

●Auto-temperature control system makes the temperature control more direct viewing and the parameter more precise.

●Self-cleaning, when stopping, can be cleaned without disassembling.

●According to different screw design rates to meet different technology request.

●This equipment has a wide raw material range, multi-shape products, and flexible collocations. The equipment produce different products according to the different models and configurations.

Productive Capacity:

According to different configurations of the production line, the output range is 100kg/h--800kg/h

Video of the Production Line Working:

Breadcrumb Samples:

If you have any needs, please pay attention to them and we will reply to you as soon as possible

Chinese

Chinese English

English Russian

Russian